With a sharply increasing cost of chemical regeneration and waste neutralization, as well as liabilities attributed to storing and handling hazardous chemicals, most industries are out searching for alternatives to produce on-site ultra-pure water. One excellent alternative is continuous electrodeionization (CEDI or EDI). This technology is often used as a key part of a larger ultrapure water system.

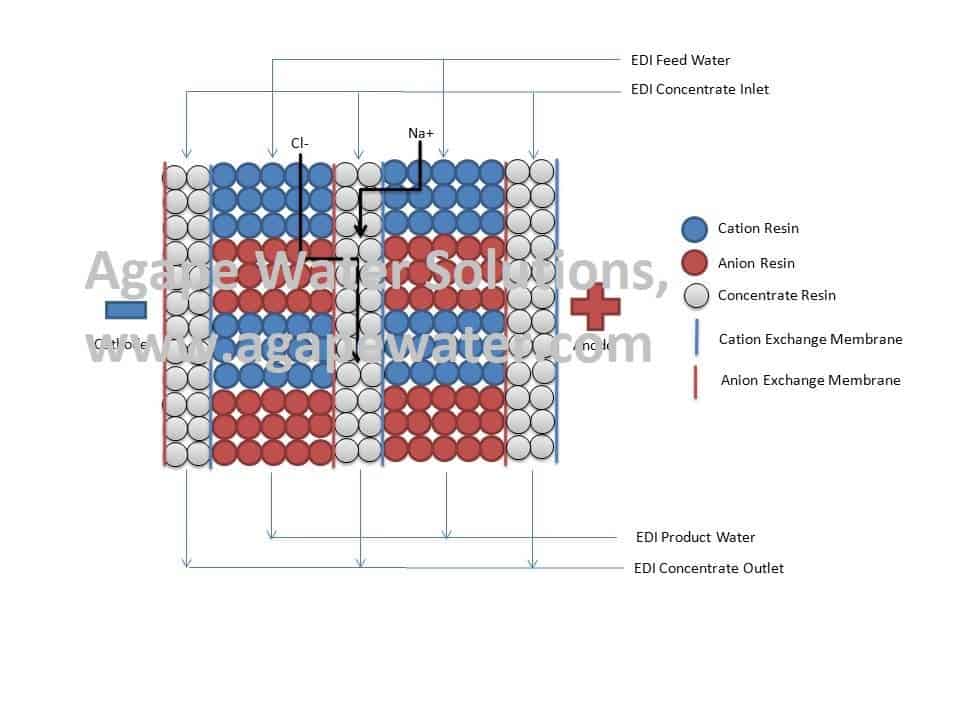

The electrodeionization system utilizes a combination of ion-exchange resins and membranes together with a direct current to separate dissolved impurities from the water. The EDI modules or stacks contain a number of cell pair between an anode and a cathode. A cell pair consists of a dilute compartment for the purifying or dilution water of ions and a concentrating compartment for concentrating and removing the ions. Between the D and C chambers are cation and anion ion exchange membranes.

When a direct current is passed through the cell, cations migrate across the dilute compartment towards the cathode through the cation permeable membrane. Anions migrate towards the anode through the anion permeable membrane, leaving ultra-purified water in the dilute compartment.

Here are five factors to keep in mind when choosing an electrodeionization system for your plant.

1. Flow Rates

An electrodeionization system is not subject to quality disparities common in batch water treatment solutions. With a continuous operation, you may need to accurately calculate your processing demands. While Mixed Beds are usually thought of as having no waste water, in fact a large volume of product water is required for chemical dilute and rinse during the regeneration. With Electrodeionization, the system is usually designed for 90-95% recovery, but the EDI wastewater often be recovered back into the raw water feed, effectively operating at 100% recovery.

EDI system providers have different machine capacities for industrial use that range from under 1 GPM to over 2000 GPM. Your intended use for the ultrapure water may accurately determine the flow rates that you desire.

There are 3 different product flow ratings for EDI modules: minimum, nominal and maximum. Nominal flow rating the “sweet spot” where performance and pressure drop are optimal. Minimum flow rating is usually about half of nominal rating, and the system should not be operated below minimum levels. The maximum flow rate is the maximum rating of the unit, but performance and pressure drop usually suffer when exceeding the nominal rating.

2. Feed Water

Feed water plays an important factor when selecting the EDI system. Not only is the feed water conductivity important but the engineers should also consider hardness, CO2, silica, organics and other contaminants. It is important to also consider any variability that may occur due to seasonal changes and salt passage increase due to age of RO membranes and operating conditions.

3. Product Water Requirements

The product water requirements are a key factor in selecting and designing an EDI system. It is important that the EDI system produce reliable product water that meets your unique requirements for years to come. While most EDI systems produce about 17 MegOhm-cm or better, often that requirement is not necessary for the water usage. In some cases a smaller unit operating above nominal flow rate, or a lower cost EDI system may be used. Be sure your EDI supplier has the expertise necessary for providing EDI systems. Many customers are surprised to find out their EDI system was not designed properly after the system is purchased and installed. Avoid that problem by working with the best – Agape Water Solutions.

4. Customization

You may have limited space available, or want your system to communicate over your DCS network, or prefer a special brand of instruments, valves or have unique requirements. Do not settle for a standard off the shelf system when Agape Water Solutions can provide the exact solution you want.

5. Ease of Operation

Electrodeionization technologies are highly automated, requiring minimal supervision for the few valves. You may need to pick a high-performance EDI system whose operation can be accomplished by your typical plant operators. Automatic control systems, regular training, and remote monitoring capabilities can ensure that your water treatment systems remain in top condition for years to come.

Get the Right Electrodeionization System Today

An electrodeionization system is an energy-efficient, eco-friendly solution to producing ultrapure water for industrial use. You may need to find the right EDI technology for your plant. If you have any questions about the different electrodeionization systems available, contact Agape Water Solutions. We also offer other water solutions including reverse osmosis water filtration.