Electrodialysis Reversal Systems treat high TDS waters including brackish water and RO concentrate waste water, blow down water and sequential batch reactor (SBR) effluent and oil and gas field produced water.

How does EDR work?

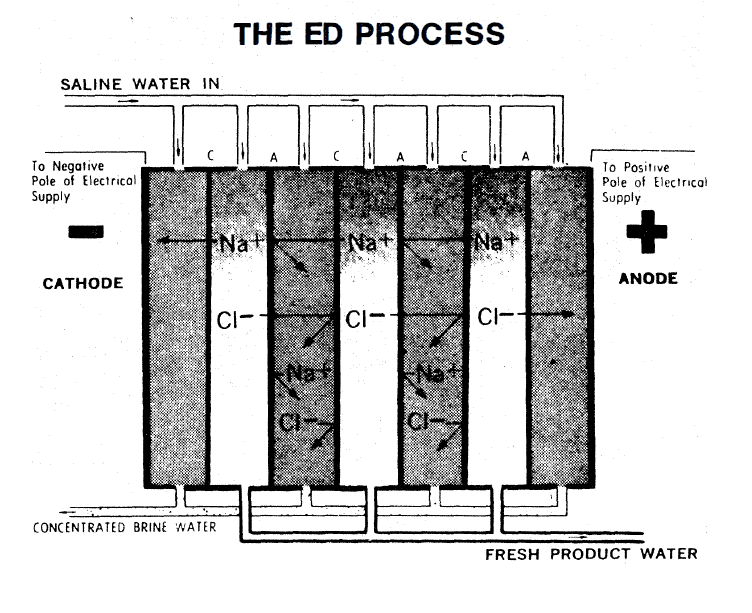

- A positively charged electrode. This is called an anode

- A negatively charge electrode. This is called a cathode

- A flow path for feed water to be purified and diluted of ions. This is called a D-chamber.

- A flow path for waste water to be concentrated with ions being removed. This is called a C-chamber.

- Cation Exchange membrane to allow positively charged ions to migrate from D to C chambers

- Anion Exchange membrane to allow negatively charged ions to migrate from D to C chambers

The positively charged ions are attracted to the cathode, and negatively charged ions are attracted to the anode. The ions flow through the ion exchange membranes into the concentrate stream. As water flows through D stream, it is desalted and exits as EDR product water. The C stream is concentrated with salts, and are sent to drain. A small percentage of the water is sent across the electrodes and is called electrode flush or electrolyte.

After an adjustable interval of operation, EDR reveres the polarity and flow path to reduce scaling. The cathode becomes the anode and the D-flow becomes C-flow. Likewise, the anode becomes the cathode and the C-flow becomes D-flow. This reversal step allows scale that may started to form on one membrane be electrochemically removed.

Agape Water Electrodialysis Reversal Systems

Agape Water Solutions provides EDR systems around the world. We have significant experience with the Evoqua Nexed technology, as the first OEM to adopt the technology and build the first pilot systems. Agape Water also build the first commercial Nexed system as well as the EDR system used by Evoqua in treating was for building EDI and EDR modules.

Our standard systems include:

- Nexed or Suez EDR modules

- Optional cartridge filter

- Automatic valves

- Instrumentation

- Concentrate recirculation

- DC power supply with reversal capability

- Automatic controls

Optional features:

- Pressure transmitters to monitor data remotely

- Data trending

- Remote monitoring on site or off site.

- Start up and training

- Service, troubleshooting and cleaning assistance

Do You Have An Upcoming Project?

If you have an up coming project to discuss, we would love to hear from you.

Our experts are on hand to provide you with sound advice about your project.