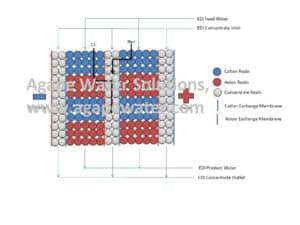

Internal flow path of electrodeionization process.

Ultrapure water is essential for advanced manufacturing plants, for example: pharmaceuticals, energy production, and microelectronic industries. Many end users now seek water treatment technologies with lower pollution loads and elimination of regeneration chemicals.

Traditionally, industrial water treatment systems relied on ion exchange units that used synthetic ion exchange resins. The resins would need to be regenerated through the use of sulphuric or hydrochloric acids and sodium hydroxide caustic soda. The rejected water demanded neutralization and local permitting and before discharge.

More industries now utilize two complimentary systems as alternatives to ion exchange. These are electrodeionization technology (EDI) and the reverse osmosis system (RO). This scalable water solution produces high-quality water while eliminating 100% of chemicals used in ion exchange regeneration.

What Is Electrodeionization?

An electrodeionization module or stack is a technology that incorporates both electrodialysis and ion exchange principles to produce high purity water. Continuous electrodeionization is often used as a crucial part of a larger ultrapure water treatment unit. Over the last two decades, the refinement of the EDI technologies has increased performance, reduced maintenance costs, and reduced electrical consumption.

How Does Electrodeionization Work?

The “cell pair” is the building block of EDI. The cell pair contains strong cation and anion resins packed between a cation exchange membrane and an anion exchange membrane. Only the appropriately charged ions to be removed can pass through the membrane. Multiple cell pairs are sandwiched between two electrodes. The electrodes provide a DC-powered electrical charge with cathode and anode terminals.

As the water passes between the ion exchange resins, the DC voltage causes cations to move towards the cathode while the anion-exchange resins remove the negatively charged ions. The active removal of ions causes a drop in conductivity in the water, passing through as the ions become trapped in concentration chambers.

Simultaneously, as water passes through the cell pair a small amount of water molecules (H2O or HOH) are split into hydrogen ions (H+) and hydroxide ions (OH-). The hydrogen and hydroxyl ions continuously regenerates the resins for ultra pure water treatment.

Here are the benefits of electrodeionization solutions

1. Lower Operation Cost

On-site continuous electrodeionization is one of the most cost-effective methods to produce high-quality water for industrial applications. There is less need for chemicals necessary for regeneration in ion-exchange systems. EDI also eliminates the need for neutralization units, local permitting, and other costs of chemicals such as corrosion damage and operator safety.

2. Consistent Water Quality

Electrodeionization technology water is not subject to quality disparities due to batch productions common in ion exchange systems. EDI utilizes a simple continuous operation that allows for consistent water quality. It leads to the production of a constant flow of deionized water.

3. Less Pollution and Safe Operation

EDI completely eliminated the need for regeneration and regeneration chemicals. Research shows that EDI eliminates the need for water treatment chemicals by up to 95%. The constant regeneration of the resins means there are no dangerous rejects and hazardous effluents. Enjoy environmental benefits by switching to an Electrodeionization system.

The elimination of chemicals results in a safer operation. Hazardous chemicals are not required, and there is less risk to people and accidental discharge.

4. Low Maintenance Needs

EDI technologies utilize a simpler process that results in fewer automatic valves and complex sequences that reduce the need for constant supervision. The simple water treatment process may only demand frequent electrode changes as part of the maintenance schedule. You can save on the lower labor costs needed to run your system.

Ultra-purified water is critical in various operations in manufacturing industries, including pharmaceuticals and semiconductor production. Electrodeionization is an excellent way to get a continuous flow of high purity water with less reliance on polluting chemicals. Agape Water Solutions is the leader of electrodeionization, and our personnel are pioneers in the industry since 1995. We can supply your plant with a custom-designed Electrodeionization unit that can fit your needs.