Ultrapure Water is the highest purity and treated levels beyond drinking water. Drinking water contains salts and other contaminants that our bodies may tolerate but manufacturing and laboratory processes will not. Agape Water Solutions delivers Ultrapure Water to meet the end users’ specific requirements. Each industry has different requirements.

Electronics Grade Water is the most rigorous level of purity. Semiconductor or Microelectronics manufacturers require the lowest level of ions measured even below parts per trillion levels, as well as low levels of Total Organic Carbon, Boron, Silica and dissolved gases.

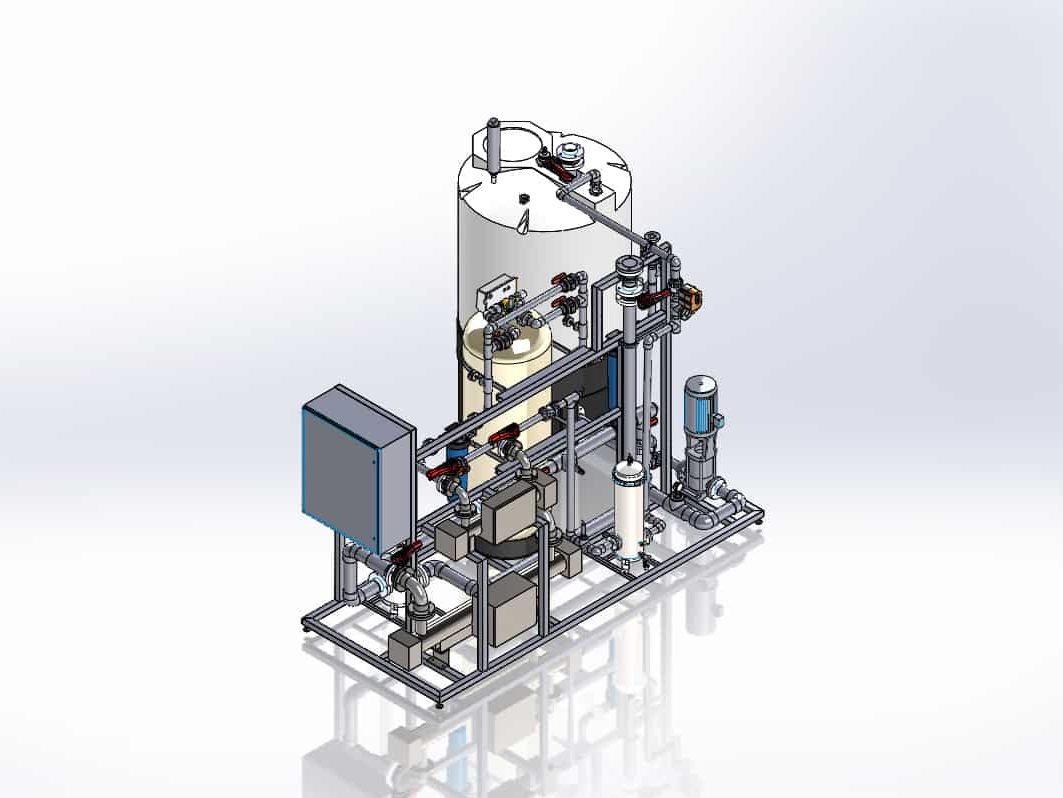

Power Plants use high flow rates of Demineralized (Demin) water. Agape Water Solutions designs systems using filtration, reverse osmosis and Continuous Electrodeionization as well as ion exchange technologies to achieve low conductivity and low silica levels. Nuclear Power has even more stringent requirements for its make up water systems. Agape Water Solutions provides a nuclear power plant of 1800 gpm of EDI product water.

Pharmaceutical, Biotech and Life Sciences users require water that meets or exceeds USP standards. Agape Water Solutions works with engineers and end users to ensure the system produces low conductivity and low levels of bacteria and organics that are required. Membrane based Water For Injection or WFI systems are available. These systems do not use distillation but instead utilize RO or UF to achieve equal to or superior to distillation including conductivity, TOC and endotoxins. Agape Water Solutions provides documentation required to validate purified water systems, and an option for Hot Water Sanitization up to 80 deg C.

Agape Water Solutions also provides laboratory grade systems for Pharma Research, Hospitals, Medical Research, Clinical Diagnostics. These systems are required to be highly reliable, simple to operate, and produce high quality water. Agape Water Solutions systems exceed to standard the customers require including American Society for Testing and Materials (ASTM) D1193-06, Clinical Laboratory Standards Institute (CLSO) Clinical Laboratory Reagent Water (CLRW).

Food and Beverage systems are provided also.

| wdt_ID | Value | USP | ASTM Type 1 | ASTM Type 2 | ASTM Type 3 | ASTM Type 4 | Clinical Lab Reagent Water |

|---|---|---|---|---|---|---|---|

| 1 | Resistivity (MΩcm) | > 18.0 | > 1 | > 4 | > 5 | > 10 | |

| 2 | Conductivity (µS/cm) | < 1.3 | < 0.056 | < 1 | < 0.25 | < 0.2 | < 0.1 |

| 3 | pH | - | - | - | - | 5-8 | - |

| 4 | TOC (ppb) | < 500 | < 50 | < 50 | < 200 | - | < 500 |

| 5 | Sodium (ppb) | - | < 1 | < 5 | < 10 | < 50 | - |

| 6 | Silica (ppb) | - | < 3 | < 3 | < 500 | - | - |

| 7 | Chloride (ppb) | - | < 1 | < 5 | < 10 | < 50 | - |

| 8 | Bacteria (cfu/ml) | < 100 | 1A: < 10/x1000, 1B: < 10/100, 1C: < 100/10 | - | - | - | < 10 |

| 9 | Particulate matter | - | - | - | - | - | 0.22 micron |

UPW Piping Concerns

The piping requirements vary by industry. Agape Water Solutions can supply ASME welded stainless steel, CPVC, PVC for power. Other processes may require Ultrapure grade IR welded or bead and crevice free (BCF) polypropylene (PP) or PVDF.

UPW Storage and Recirculation

Each grade of water will have its own storage and recirculation requirements. The tank size, turnover, loop flow rate, polishing, UV, and filtration should be considered. It is not enough that the water entering the tank meet the users requirements, but the water delivered to point of use (POU). Water that is not continuously recirculation or polished or even some that have tanks vented to atmosphere may cause contamination.

Do You Have An Upcoming Project?

If you have an up coming project to discuss, we would love to hear from you.

Our experts are on hand to provide you with sound advice about your project.